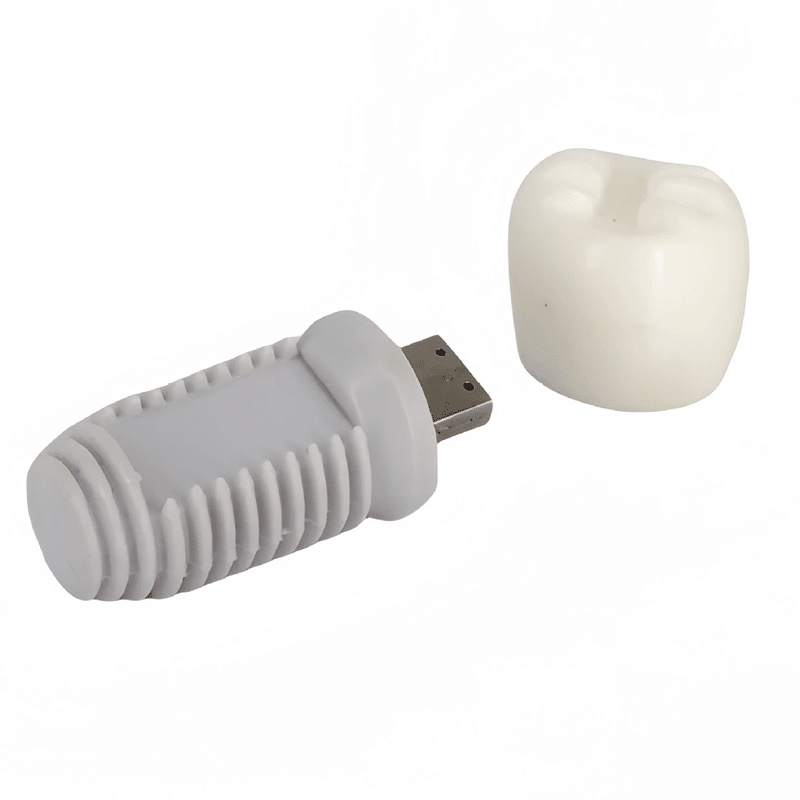

Best Quality Customized Dental Implant Pendrive USB 2.0

-

Competitive Wholesale Pricing – Factory-direct pricing model for bulk orders of 500 pcs or more, helping wholesalers and distributors maintain strong margins while sourcing reliable pendrive usb 2.0 products for medical and dental markets.

-

Advanced Customization Options – Full OEM/ODM support including custom PVC mold design, logo printing, color matching, packaging customization, and memory configuration for pendrive 2.0 promotional and professional use.

-

Consistent Quality & Stability – Each unit is produced using certified flash memory chips and strict QC processes, ensuring the performance and durability expected from the best usb 2.0 pen drive suppliers.

-

Stable Lead Time & Scalable Supply – Dedicated production lines for bulk pendrive orders allow us to meet tight schedules, seasonal campaigns, and long-term supply contracts without interruption.

-

Wide Application Scenarios – Ideal for dental clinics, implant manufacturers, healthcare distributors, trade shows, and educational promotions requiring customized pendrive 2.0 solutions with professional branding impact.

What Is the Dental Implant Pendrive USB 2.0 for Wholesale Buyers

The Dental Implant pendrive is a custom-shaped PVC USB flash drive developed specifically for dental, medical, and healthcare branding applications. Unlike standard generic storage devices, this product is designed to visually replicate a dental implant, making it highly relevant for dental clinics, implant manufacturers, laboratories, and healthcare marketing campaigns. From a wholesale perspective, this pendrive is positioned as a value-added promotional and professional tool rather than a consumer retail item.

As a manufacturing factory, we produce this pendrive 2.0 using industrial-grade PVC materials combined with stable flash memory components. The internal structure follows standard USB 2.0 protocols to ensure broad compatibility and reliable performance across Windows, macOS, and Linux systems. For wholesalers, this means the product can be confidently marketed as a best usb 2.0 pen drive option for professional distribution, educational use, and long-term brand exposure without concerns about usability or system limitations.

Why the Pendrive USB 2.0 Is Ideal for Custom Wholesale Programs

The primary reason wholesalers choose a custom-shaped pendrive is its ability to deliver strong brand recall while remaining functional and professional. In B2B healthcare and dental markets, branding tools must communicate trust, precision, and industry relevance. A dental implant–shaped pendrive naturally aligns with these values, making it significantly more effective than standard promotional USB drives.

From a cost-performance standpoint, the pendrive 2.0 platform remains one of the most stable and economical interfaces for bulk production. For large-scale orders, it allows wholesalers to control unit cost while still offering a product that meets expectations associated with the best usb 2.0 pen drive category. This balance between affordability, customization depth, and functional reliability is critical for wholesalers managing competitive pricing and long-term customer relationships.

Who Should Purchase This Pendrive USB 2.0 in Bulk Quantities

This pendrive usb 2.0 is developed exclusively for B2B buyers, particularly wholesalers, importers, and distributors supplying promotional products to the dental and medical industries. Typical buyers include promotional gift wholesalers, dental equipment distributors, healthcare marketing agencies, and OEM brand owners who require consistent quality and repeatable customization across large volumes.

The product is especially suitable for customers capable of placing custom orders of 500 pcs or more. At this volume level, wholesalers benefit from optimized mold costs, stable unit pricing, and greater flexibility in branding and packaging. For these buyers, selecting a pendrive 2.0 from a factory-direct supplier ensures access to production planning, quality control transparency, and scalable supply — all essential factors when positioning a best usb 2.0 pen drive solution in professional B2B channels.

When to Order Pendrive USB 2.0 for Maximum Cost Efficiency

Timing is a critical factor in wholesale procurement. Ordering a pendrive well in advance of exhibitions, product launches, conferences, or annual marketing campaigns allows sufficient time for sampling, branding approval, and production scheduling. Early orders also help wholesalers avoid peak-season manufacturing congestion, which can impact lead times and pricing.

For long-term buyers, establishing a rolling or forecast-based order plan for the pendrive 2.0 significantly improves supply stability. Many wholesalers choose to lock in designs and specifications for repeated production runs, ensuring consistent pricing and faster turnaround. This approach reduces procurement risk and supports uninterrupted supply of a best usb 2.0 pen drive across multiple sales cycles or client programs.

Where the Pendrive USB 2.0 Is Manufactured and Distributed

All pendrive products are manufactured in our dedicated production facility, which integrates PVC molding, chip assembly, data programming, and quality inspection under one roof. Factory-direct manufacturing allows us to maintain strict control over materials, dimensions, logo accuracy, and internal performance, ensuring every pendrive batch meets consistent standards.

From a distribution perspective, our pendrive 2.0 products are supplied globally to wholesalers serving dental clinics, hospitals, implant brands, and healthcare marketing companies. The neutral OEM structure allows buyers to brand, package, and position the product according to their local market requirements. This flexibility is essential for wholesalers offering the best usb 2.0 pen drive solutions across different regions and customer segments.

Which Standards and Custom Options Apply to Pendrive USB 2.0 Orders

Quality and compliance are non-negotiable in B2B procurement. Our pendrive can be produced in accordance with common international standards such as CE and RoHS, depending on the destination market. This ensures wholesalers can integrate the product into regulated markets without additional compliance risks.

In terms of customization, the pendrive 2.0 supports a wide range of options including custom PVC mold shape, logo printing or embossing, color matching, memory capacity selection, and packaging customization. Importantly, these customization options do not compromise performance or durability, allowing wholesalers to confidently market the product as a best usb 2.0 pen drive within professional and promotional contexts.

Technical Specifications

| Specification Item | Details |

|---|---|

| Product Type | Custom Shaped PVC Pendrive USB 2.0 |

| Interface | USB 2.0 (High Compatibility) |

| Storage Capacities | 1GB / 2GB / 4GB / 8GB / 16GB / 32GB / 64GB (Optional) |

| Material | Durable, Flexible PVC |

| Shape | Dental Implant (Custom Mold) |

| Customization Options | Logo Printing, Embossing, Color Matching, OEM Branding |

| Data Transfer Speed | Standard USB 2.0 Performance |

| Compatibility | Windows, macOS, Linux |

| Certifications | CE, RoHS (Available per Market Requirement) |

| MOQ | 500 pcs (Custom Orders) |

| Usage Scenarios | Dental Marketing, Medical Promotions, Patient Education |

| Packaging Options | Bulk Packing / Custom Retail Packaging |

| Production Lead Time | Sample: 5–7 Days / Mass Production: 12–20 Days |

How the Pendrive USB 2.0 Is Customized, Produced, and Delivered

The production process for a custom pendrive begins with design confirmation and sample approval. Once specifications are finalized, mold preparation and material selection are completed, followed by mass production. Each unit undergoes functional testing to verify data transfer stability and physical inspection to ensure branding accuracy and structural integrity.

For wholesalers, this structured workflow provides predictability and transparency. Orders of 500 pcs or more benefit from dedicated production planning, controlled lead times, and batch-level quality assurance. By working directly with the factory, buyers gain a reliable supply of pendrive 2.0 products that meet professional expectations and reinforce their reputation as suppliers of the best usb 2.0 pen drive solutions in the healthcare and dental markets.

Conclusion

The Customized Dental Implant pendrive usb 2.0 is designed to meet the real-world procurement requirements of B2B wholesalers who prioritize cost control, customization flexibility, and supply reliability. As a factory-direct manufacturer, we offer this pendrive as a scalable solution for buyers placing custom orders of 500 pieces or more, ensuring consistent quality, stable pricing, and repeatable production for long-term programs. Its industry-specific dental implant design enhances brand relevance while maintaining the functional reliability expected from a professional pendrive 2.0 product.

For wholesalers and distributors supplying dental clinics, implant brands, and healthcare marketing channels, this product delivers measurable value beyond standard promotional storage devices. Supported by controlled manufacturing processes, compliance-ready materials, and flexible OEM/ODM customization options, it can be confidently positioned as a best usb 2.0 pen drive for professional and promotional use. By partnering directly with our factory, B2B buyers gain a dependable custom pendrive 2.0 supply chain that supports growth, protects margins, and strengthens long-term customer relationships.

Related products